June 20, 2021 | Journal of Cleaner Production | Source |

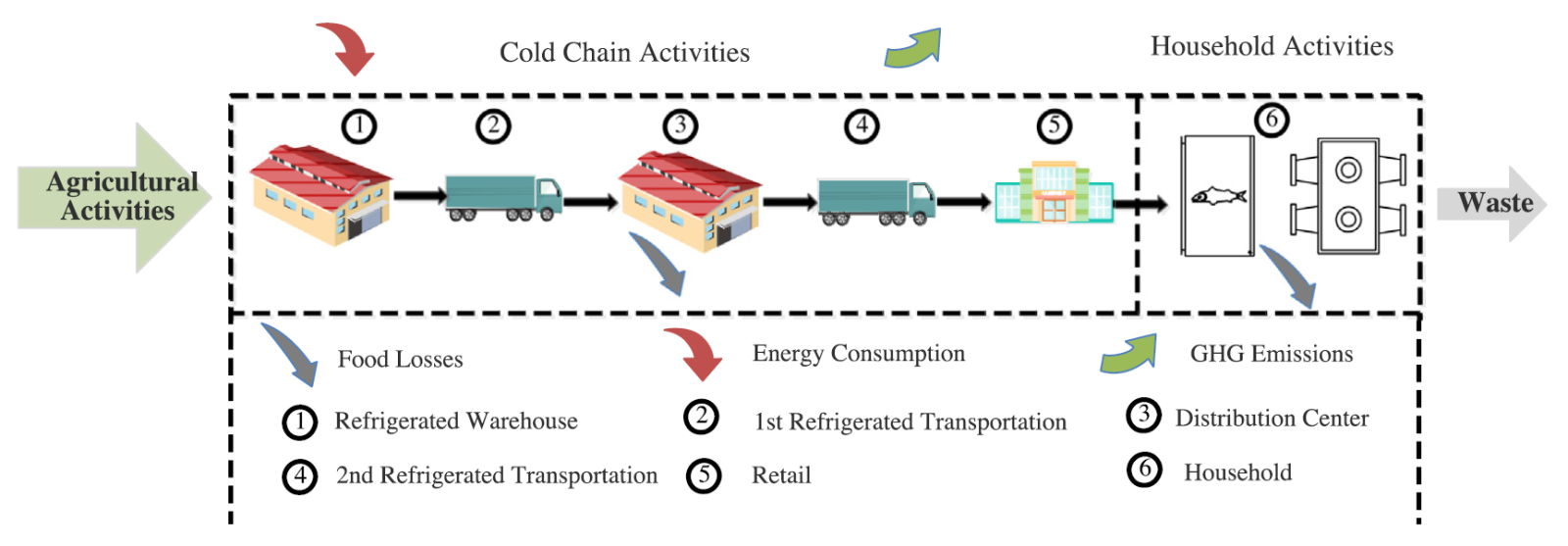

Introduction: Researchers from the University of Michigan (USA) analyzed the lifecycle GHG emissions of perishable foods—vegetables, fruits, meat, and aquatic products—delivered by China’s cold chain. With the cold chain market projected to nearly double between 2019 and 2026, understanding its climate impacts is crucial. The study addresses a knowledge gap by examining the trade-off between reducing food losses and the emissions generated by refrigeration. Using a cradle-to-consumption lifecycle assessment (LCA) with 1 kg of edible food consumed as the functional unit, the research integrates inventory data, Monte Carlo simulations, and sensitivity analysis of 22 parameters. It focuses on post-agriculture emissions from three key sources: refrigerant leakage, energy use, and food loss and waste (FLW).

Key findings: Agriculture dominates lifecycle emissions, especially for meat and aquatic products (74–89%), yet cold chain and household stages remain significant. For fruits and vegetables, agriculture and cold chain each contribute about 47% of total emissions. Within post-agriculture stages, emission sources differ: in meat/aquatic scenarios, households, retail, and refrigerated warehouses are largest contributors, with household shares reaching 31–41% in medium-temperature (MT) cases. For fruits and vegetables, most emissions stem from warehouses and first refrigerated transport. Lower-temperature (LT, frozen) storage increases impacts; for example, LT meat generates 1.7 kg COâ‚‚eq/kg more than MT meat due to longer storage times.

By source, energy use drives 61% of post-agriculture emissions in fruit/vegetable cases, while FLW dominate in meat/aquatic products, magnified by their high embodied carbon. At the national level, a fully developed cold chain could add 280–400 Mt COâ‚‚eq annually, about 3% of China’s 2018 total emissions. Sensitivity analysis highlights storage time, food loss rates, and agricultural emission intensity (Cfood) as key drivers. Mitigation options include improving refrigeration efficiency, adopting low-GWP refrigerants, using renewable energy, shortening storage durations, and reducing consumer food waste. Overall, cold chains help prevent spoilage but must be paired with technological upgrades and behavioral changes to secure net climate benefits.

Figure | The lifecycle of food product and cold chain system boundary. The complete lifecycle of perishable food product starts from agriculture activities and then is delivered through cold chain logistics. The post-agriculture activities are focused on this paper.