May 16, 2024 | Nature Food | Source |

Introduction: The current ammonia production is centralized in large chemical manufacturing facilities, making nitrogen fertilizer production vulnerable to high transportation costs and fossil fuel price fluctuations. Global research team led by Carnegie Institution for Science in the U.S. explores electrified ammonia production based on electric Haber–Bosch and electrocatalysis in small, decentralized production facilities within areas serviced by public power grid or powered by solar agrivoltaic systems or grid electricity.

Key findings: Decentralized production could become cost-competitive with traditional centralized methods, especially when accounting for transport costs and supply chain disruptions. By 2030, up to 96% of global ammonia demand could be met cost-effectively through decentralized production. This shift would benefit regions with food insecurity and reduce dependence on fossil fuels, cutting carbon emissions. Cost evaluation is performed by comparing decentralized production with historical ammonia market prices. Findings indicate that decentralized technologies, particularly those connected to the grid, could significantly lower fertilizer costs. Agrivoltaic systems would stabilize prices but require additional storage for continuous operation.

Decentralized ammonia production offers advantages such as reduced need for storage, lower risk of nitrogen loss during transport, and independence from fossil fuel price swings. Overall, this approach could transform the fertilizer industry, promoting sustainable agriculture and enhancing global food security.

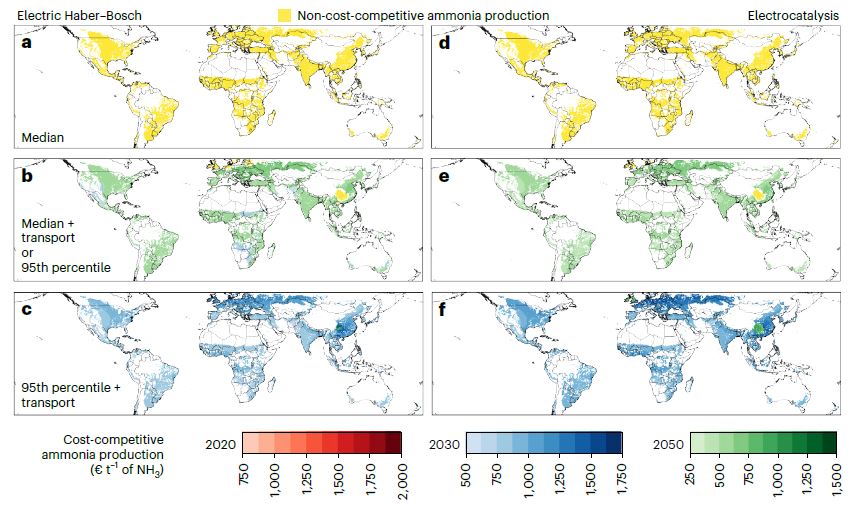

Figure | Location of ammonia demand on croplands in the current scenario supplied by either decentralized electric Haber–Bosch or decentralized electrocatalysis in the grid-connected configuration. For each pixel, the cost of ammonia production from decentralized technologies is determined based on the earliest year that achieves cost-competitiveness among 2020 (red), 2030 (blue) and 2050 (green). The cost of decentralized production is compared with the cost of ammonia production from centralized production and the cost of ammonia at the demand point, inclusive of the cost of transport. Reference costs of ammonia production from centralized production are €390 t−1, €780 t−1 and €1,063 t−1 of NH3, chosen from the median, 95th percentile, and maximum prices of the historical ammonia market price, respectively. In addition, the cost of logistics for transporting ammonia is added to the three prices, resulting in a twofold increase in the price of ammonia at the demand point. a,d, Ammonia production by decentralized electric Haber–Bosch (a) or decentralized electrocatalysisis (d) is never cost-competitive with centralized fossil-based production under low market prices from centralized production and excluding the cost of transport of ammonia. b,c, Cost-competitiveness based on electric Haber–Bosch is reached for the projected technological development in 2030 and 2050 and in comparison with the median cost of production combined with the cost of transport (equivalent to the 95th percentile cost of ammonia production) (b) and the 95th percentile cost of production with the additional cost of transport (c). e,f, Cost-competitiveness based on decentralized electrocatalysisis is reached for the projected technological development in 2030 and 2050 and in comparison with the median cost of production combined with the cost of transport (equivalent to the 95th percentile cost of ammonia production) (e) and the 95th percentile cost of production with the additional cost of transport (f). Yellow-coloured pixels represent regions where decentralized production is not cost-competitive.